Air jet Mill is shearing action grinding and collecting operations for achieving ultra-fine grinding upto 0.4 micron to 15 microns* depending upon the nature (Physical & Chemical Property) of the product. Air jet mill (also known as micronizer) is designed for grinding hygroscopic, heat sensitive and explosive materials to achieve consistent steep particle size distribution. Air Jet Mill allows greater control over the grinding parameters and product particle size distribution

Model Available :

- Pneumatic bag shaking model.

- Reverse pulse jet model.

- For isolator application.

- For containment application.

Working Principle

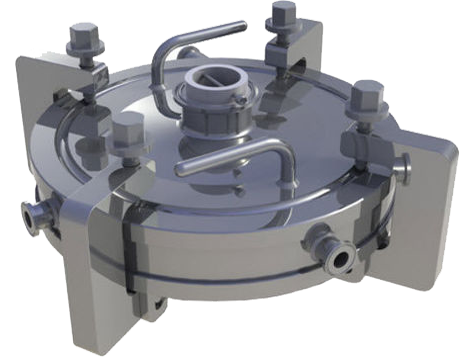

Jet Milling is a concept of feeding powder particles into a flat circular milling chamber and subjecting the same tangentially with pressurized air or nitrogen through a venturi. The Powder Particles are accelerated in a spiral movement inside the milling chamber by a number of angular holes in a ring and placed around the periphery of the chamber.

The heat-sensitive and low melting point materials are easily micronized. Micronizer takes place due to the collision between the incoming particles and the particles, which are already accelerated into the spiral path, The larger Particles of the product get retained at the periphery of the chamber by centrifugal force and the smaller particles exit with the exhaust air from the central portion of the chamber.

The material can be milled to an average particles size of 0.2 to 5 micron or coarse ground to 400 mesh depending upon characteristics of the product.

The milling action of the particle is because of the high velocity of air/gases instead of pins, jaws or hammers and because of this heat does not get generated during milling. The adiabatic expansion of compressed air takes place with the resultant cooling effect. The heat-sensitive and low melting point materials are micronized without use of freeze grinding methods.

- Jet Mills are widely used in the manufacture of drugs and pharmaceuticals, organic and inorganic pigments, optical brighteners, fluorescent pigments, food colour synthetic dyes, metal (except malleable metals) carbides & borides, herbicides and pesticides, ceramic glasses, alumina, feldspar, frit, kaolin, mullite, electronic grade materials such as materials required for semiconductors, phosphors, photo electronic, high-temperature critical materials and rocket solid fuels, etc.

- We are jet mill manufacturer, supplier, and exporter of multiple variety manual and fully automated jet mill micronizer, micro pulverizer, and spiral fluidize air with the industrial requirement.

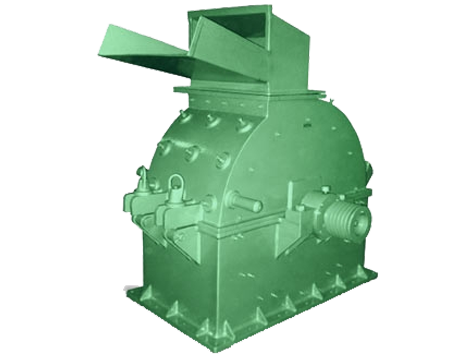

| Mill | Main Motor HP | Rotor RPM | Classifier Motor HP | Classifier RPM |

|---|---|---|---|---|

| ACM5 | 10 | 9400 | 1 | 5400 |

| ACM10 | 10 | 7000 | 15 | 5000 |

| ACM30 | 30 | 4600 | 75 | 2500 |

| ACM 30 (ID) | 30 | 5000 | 75 | 3000 |

| ACM 60. | 60 | 3000 | 15 | 2000 |

| ACM 60(ID) | 60 | 3500 | 15 | 3000 |

| ACM 75(ID) | 75 | 3500 | 15 | 3000 |

| ACM100 | 100 | 3000 | 15 | 2000 |

| ACM 100(ID) | 100 | 3500 | 15 | 3000 |

| ACM 120 | 120 | 2200 | 20 | 1800 |

| ACM 150 | 150 | 2200 | 20 | 1800 |

| ACM 200 | 200 | 2200 | 30 | 1800 |

- No Contamination and No Heat Generation

- Extreme fine powder output, more uniform & more efficient

- Most suitable for 1 micron to 15 micron particle size

- Optimal air consumption depending on the size of the mill.

- Improves solubility, dissolution & Bio availability

- Easy cleaning and Maintenance

- Dust free Operation

The micronizing of the powder improves absorption capacity of the drugs in the human body. This also results in new and unusual chemical and physical properties relating to dependability, solid-state reaction rate, texture, color, absorption, etc.

The surface area achieves an increase in potency of drugs, which reduces the dosage of the drugs. Product of 30 mesh size when jet-milled to 5 micron, has more than 160,000 particles & surface area increases more than 115 times. This results in faster reaction time for chemicals, faster ignition time in the case of solid fuels of rockets. The Jet Milled pesticides & herbicides cover much more surface area using less of the active ingredients, thus reducing the cost. The polishing powders used for polishing the lenses, computer hard disc or in toothpaste are required to be a narrow particle size distribution for maximum productivity. The abrasives used in these polishing powders are very precisely milled.

Any cosmetic product requiring silky smoothness in application can be achieved in Jet Mill. The reflectivity of light occurs when the particle size of the pigment approaches a precise relationship to the wavelength of visible light. Therefore by controlling the particle size, the product quality & its brilliance can be ascertained.

Jet Mill versions are sanitary, Indian FDA and US-FDA accepted designs, in line with GMP practices and in accordance with all pharmaceutical specifications worldwide. The Jet Mills manufactured by Promas Engineers have replaceable internal rings with optimized grinding angles for various products. The design & construction of Jet Mills is the result of many years of dependable, uninterrupted service.

We provide two types of feeding system along with the Jet Mill in accordance with the properties of the products in the human body. This also results in new and unusual chemical and physical properties relating to dependability, solid-state reaction rate, texture, color, absorption, etc.

- Vibratory type feeder : The system is more preferred by the pharmaceutical industries as it is mounted on the main platform and without bolting so as to remove it easily for cleaning. The trough of the unit is fully covered by a transparent cover. The feed rate is controlled by adjusting the vibrator to get a more accurate feed rate.

- Screw type feeder : A twin shaft feeder, volumetric type, with a concave profile, with self-cleaning screws that are able to break the agglomerates and ensure an accurate feeding of poor flowing products. The speed controlled by a step-less, mechanical variator.

WhatsApp

WhatsApp