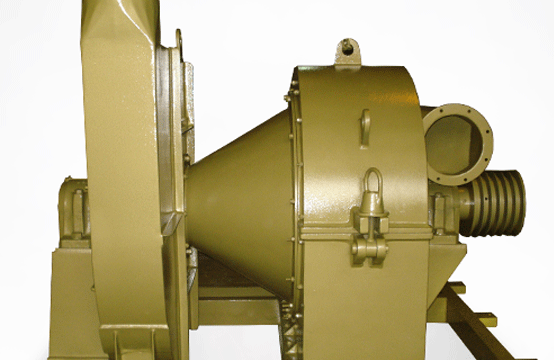

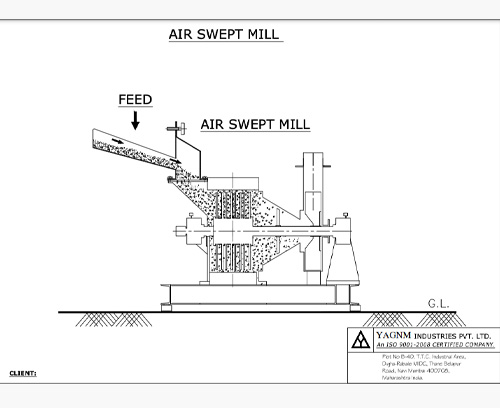

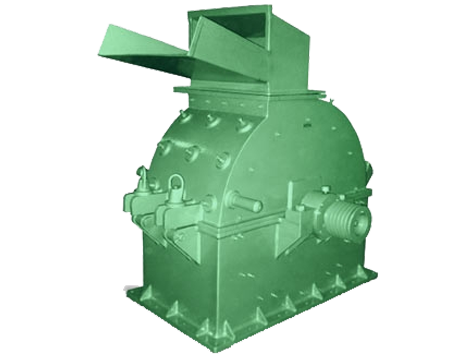

The Air Swept Mill (ASM) is a screenless pulverizer that pulverizes soft and medium-hard dry materials. During ASM, the material is fed into a grinding chamber and beaten up with a hammer lining up on the shaft. Despite being screenless, the mill's classifying action is accomplished with the help of specially designed wizards. Wizard adjustments determine the fineness of the finished product. If you move the wizard towards the hammer, it will produce a coarse output, and if you move it away from the hammer, it will produce a fine output. As the material is picked up by the blower unit, it is conveyed to the dust collector via the pneumatic conveying system. Other features can be incorporated into Air swept mill based on the application and client requirements.

Heat-sensitive products are grinded at ambient temperature by providing water cooling jackets on mills. Ayurvedic herbs & roots as well as turmeric, limestone, various minerals, chemicals, pigment, etc. are ground in air swept mills.

Working Principle

Air Swept Mill (Screenless Equipment) are recommended for micro fine pulverizing of soft to medium hard , fibrous and slightly moist materials. Mill is uneconomical where frequent change over of product is required and material is abrasive. Such Impact Mills efficiently handle fibrous materials and products having similar structure. Water circulation jacket is an optional feature, apart from different styles of grinding elements. Air swept mill machine and manufacturers, suppliers, exporters, dealers and traders in India and worldwide from Gujarat and Mumbai since 1960 as per the ISO standards with required industrial features and specifications.

Axially fed material is swept across the periphery of hammers and whizzer type retainer plate. Grinding action takes place between high speed hammers and serrated liners. Micro fine powder is discharged through a built-in blower to a cyclone separator, coupled with a dust filter unit. Mills are supplied with pneumatic conveying system.

- Air swept mills are screenless grinding machines

- These mills are provided with cooling jackets for heat-sensitive material

- Depending on the material characteristics, 150 to 400 mesh BSS can be achieved

- It uses a compact design that requires less installation space

- Materials of construction are available in mild steel and stainless steel for a wide variety of applications

- Operations are conducted dust free, waste isn't generated, and polluting norms are adhered to

- Easy to operate and maintain

- Food & spices

- Agro product

- Agro chemicals

- Fertilizers

- Metal powder

- Chemicals

- Minerals

- Dyes & pigment

- Ceramics & minerals

- Paints & Polymers

Standard Supply

| Model No. |

Mill Motor Horse Power ( H.P. ) |

Capacity ( Range ) kgs / hr / operation |

Maximum Permissible feed size (mm) |

Fineness range | Abrasiveness & Hardness handled |

|---|---|---|---|---|---|

| MP – 01 | 5 – 7.5 | 30 to 2000 | 6 | 100 to 300 mesh BSS & Finer | Low & upto 3 on Moh’s Scale |

| MP – 02 | 10 – 20 | 30 to 2000 | 6 | 100 to 300 mesh BSS & Finer | Low & upto 3 on Moh’s Scale |

| MP – 31 | 30 – 40 | 30 to 2000 | 6 | 100 to 300 mesh BSS & Finer | Low & upto 3 on Moh’s Scale |

WhatsApp

WhatsApp