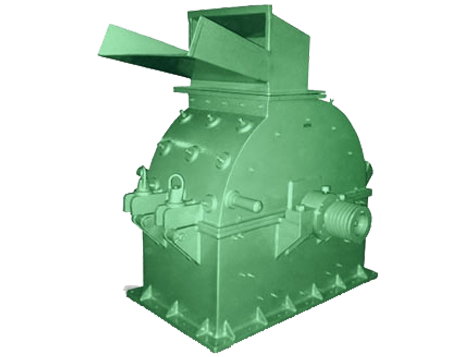

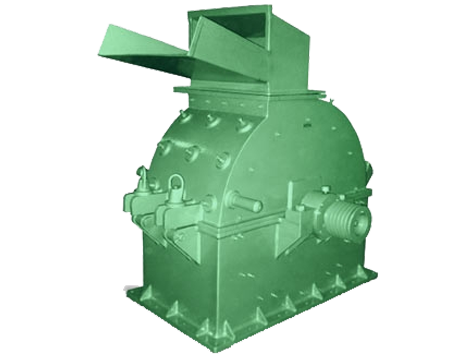

Hammer Crusher ( Screen Type Equipment ) is employed to disintegrate almost everything, from paper products to limestone and spices. Traditional disintegrators are technologically replaced by these modern and highly versatile machines, having total flexibility. Combination of different hammer styles, liner plates, sieve inserts and wear resistance technology offer almost unlimited possibilities of crushing lumpy, bulky, irregularly shaped, hard & fibrous materials, into coarse to medium fine powders.

Higher Output Low Power Consumption Easier Operation Traditional disintegrators are technologically replaced by this modern machine,having total flexibility.Combination of different hammer styles, liner plates, sieve inserts and wear resistance technology of drier offer almost unlimited possibilities of crushing bulky, irregularly shaped, hard fibrous materials, into coarse to medium fine powder. Hammer mill is subjected to rigid inspection and actual grinding tests at our experimental station before it is delivered to the stores for dispatch.

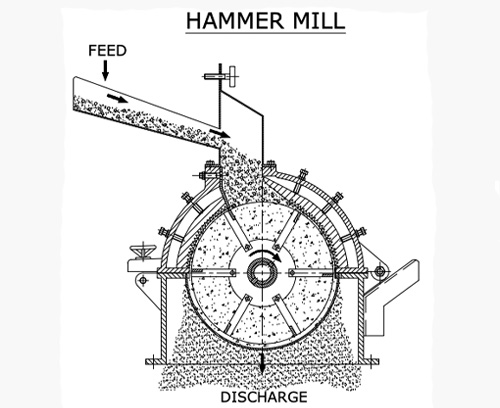

Operating Principle

Hammer Mill with Air Blower & Cyclone Separator is economical unit designed for general all round work for time saving operation. All types of products passes through a wide feed hopper into the grinding chamber. The swinging hammers, in the rotating hammer rotor, crush materials at the stationery liners before passes through a screen and rotating hammers The ground material is continuously sucked by a powerful air blower through screen and conveyed through the pipe line into the cyclone separator for bagging.

The air blower maintains constant atmospheric cool air flow in the mill chamber in order to obtain a cool product and continuously clean the screen, thus increasing the output of the ground material. The particles size of the ground material can be varied by a large range of sieves with the desired opening. The dust & ground material id gets separated in the cyclone separator. Top of the cyclone air balloon is fitted. Air balloon separate clean air & dust. The dust gets collected in air balloon. As soon as air balloon shacked the dust dropped into the cyclone separator and get collected from bottom of the cyclone separator. Whole grinding operation is carried out in a cool atmospheric temperature which prevent their oil, color & flavor from the products.

The Hammer Mill Plant Includes

- Permissible Feed Size: Upto 100mm

- Fineness Achievable: Upto 80 Mesh or 180 Microns

- Permissible Hardnsess: Upto 3 Moh's Scale

- Permissible Brittleness: Medium To High

- Permissible Moisture: Upto 3%

| Model |

Rotor Data in mm |

Chamber Width width |

Machine RPM |

Recommended Motor HP/RPM |

Over Dim. In Meter length/width/height |

Capacity Kg/hr.upto. |

|---|---|---|---|---|---|---|

| HM -MS6 | 105 | 650 | 1200-1400 | 75/100/ 1440 | 1500/ 120/ 2000 | 15,000 |

| HM -MS5 | 900 | 550 | 1400-1600 | 60/75/ 1440 | 1300 100 1650 | 10,000 |

| HM -MS4 | 750 | 450 | 1800-2000 | 50/60/ 1440 | 1100/900/1350 | 7500 |

| HM -MS3 | 600 | 360 | 2000-2200 | 30/40/ 1440 | 900/ 800/1000 | 4,500 |

| HM -MS2 | 450 | 300 | 2500-3000 | 25/30/ 2880 | 800/700/850 | 1,200 |

| HM -MS1 | 450 | 220 | 3000-3500 | 15/20/ 2880 | 800/ 600/ 850 | 750 |

| HM -MS0 | 300 | 200 | 4000-4500 | 7.5/10/ 2880 | 550/ 400/ 650 | 300 |

WhatsApp

WhatsApp