Masala Mill is one of our unique flagship products. This equipment complies with set industrial norms, using the best quality materials and components. We also readily customize these machines in different technical specifications per client requirements. Masala mills are preferred for their superior quality, efficiency, durability, and sturdiness.

These yield masalas that are hygienic and presentable. Also, we offer this equipment at cost-effective prices.

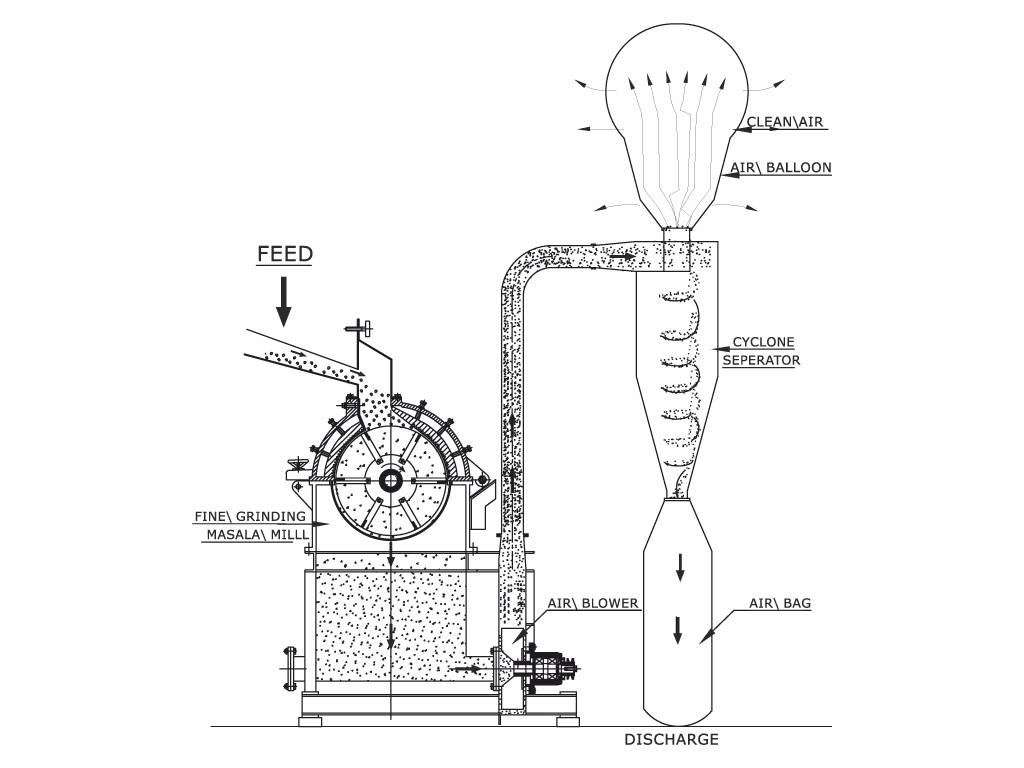

Working Principle

Masala Mill is an economical unit designed for all types of spices for time-saving operations. All spices pass through a wide Feed Hopper into the grinding chamber.

The swinging hammers in the mill chamber will crush the materials with the top stationery liners. The ground material is continually sucked by a powerful air blower through the screen and conveyed through the pipeline into the cyclone separator for bagging. The air blower maintains constant atmospheric cool air flow in the mill chamber in order to obtain a feed cool product and continuously cleans the screen, thus increasing the output of the ground material.

The particle size of the ground material can be varied by changing the desired opening of the screen. The dust & ground material get separated in the cyclone separator. The top of the cyclone air balloon is fitted. The air balloon separates clean air & dust. The dust gets collected FINE GRINDING in an air balloon as soon as the air balloon shakes, the dust drops into the cyclone separator and gets collected from the balloon of the cyclone separator.

The whole grinding operation is carried out in a cool atmospheric condition, which prevents the Volatile oil, color & flavor from the products.

WhatsApp

WhatsApp