The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery Increasing the top eccentric mass Increases the horizontal throw causing oversize material to discharge ata tasterrat The bottom eccentric weight rotates below the centre of vibrating, mass creating it on the screen giving Vibration in vertical & tangential planes, increasing the vertical component of motion which promotes turnover of material on the screen surface helping maximum quantity of undersize material to pass through the screen. The effective vertical motion helps in minimising blinding of screen by near size particles. The tangential component of motion is controlled by the angle of lead given to bottom weights with relation to top weight

Operating Principle

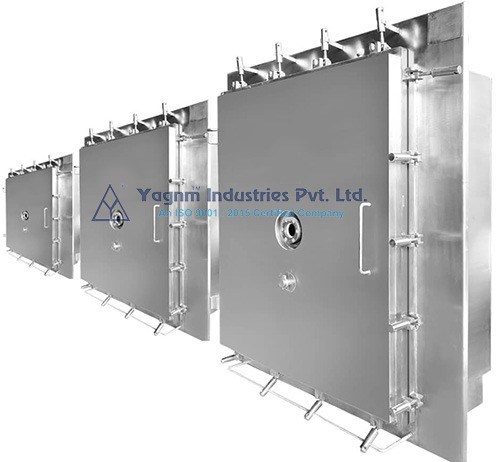

Vacuum tray dryer is the most commonly used batch dryer. They are either box-shaped or cylindrical shaped loaded and unloaded via a door. Inside this contains several heating plates mounted one above the other on which the product is placed in trays. The Top of both heating plates (Shelves) and the bottom of heating shelves trays should be as smooth as possible to permit optimal heat transfer between plates and products. The medium flowing through the heating plates is water, steam, or thermal oil. The distance between the heating plates is determined primarily by the surface loading and the foaming of the product. To avoid retrograde condensation, the cabinet walls are indirectly preheated by limpet coil provided on the outer side of the body (Optional). Only after all the product trays reach the same temperature, the cabinet is evacuated and drying can start.

During the main drying phase, the vacuum is in the range of 40 to 80 mbar abs and in the final drying phase, the vacuum of only a few mbar abs is reached. The vacuum can be controlled through PLC in order to reduce the drying cycle. Nitrogen can also be purged in the VTD according to the product.

The dimensioning of the vacuum system is an important factor in the design of drying cabinet systems. If for example vigorous foaming of the product is desired, evacuation to the operational vacuum level must take place very quickly.

- Vacuum tray dryers are used for drying of high-grade temperature and oxygen-sensitive products. Highly suitable for drying hygroscopic substances which are dried to very low residual moisture content levels.

- Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pomposity.

- We are a vacuum tray dryer manufacturer, supplier, and exporter as per ISI guidelines. We have fulfilled every customer’s requirements since 1995.

- One-touch door opening & closing system. No door Sagging.

- Machine welded heating shelves for maximum heat transfer and no contours or deformation.

- Channel type heating shelves for faster heat transfer rates.

- Online receiver drain-ability under vacuum.

- Larger diameter vacuum suction pipe for minimal choking and maximum vapor suction.

- Single piece gasket for Door ensuring no leakage.

- Completely welded body.

- World-class aesthetics.

WhatsApp

WhatsApp