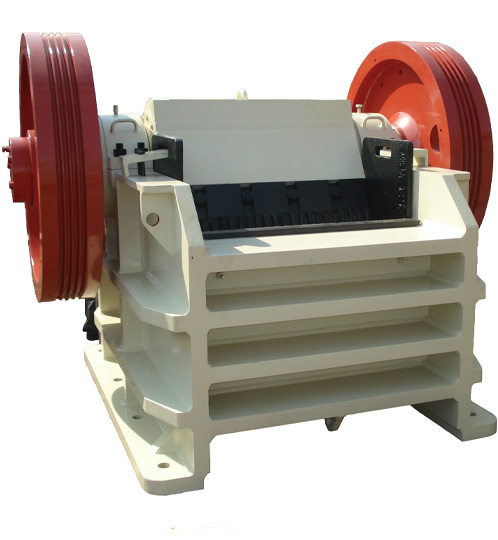

"YAGNM" Crushers bodies are fabricated from high class quality ultrasonically tested steel plates (IS 2062). Ribs are provided along the line of stress to give maximum strength and minimize vibration.

The general construction detail-

Main Frame(Body):

"YAGNM" Crushers bodies are fabricated from high class quality ultrasonically tested steel plates (IS 2062). Ribs are provided along the line of stress to give maximum strength and minimize vibration.

Eccentric Shaft

An EN series Carbonsteel shaft is used, which is finished to a high degree of accuracy to give an exact stroke to the swing jaw. The raw material is ultrasonically tested & then hardened to ensure a long life.

Roller Bearing

Heavy duty self-aligning sperical double roller are fitted to give smooth and economical running of the machine. The bearing used withstand very heavy loads and fluctuations on the line of action of the shaft.

Jaw stock

The Jawstock (levers) is made of high quality cast steel castings (IS 1030) with deep webbing to give it great strength. The bearings seat (bore) of the jaw stock is given very high finish using carbide tools.

Toggle Mechanism

C.I. Toggle Plates are used which act as a "fuse", in case of overloads. They are seated on tempered toggle bearings.

Jaw Plates

Jaw Plates are made of high grade Chrome-Manganese steel and they can be reversed end to end, to give maximum life to each jaw plate.

Side Wearing Plate

They are also made of high grade Chrome-Manganese Steel which saves the body from wearing.

Fly Wheel

Well balanced large diameter flywheels (Flat and "V") are provided, which can be interchanged from side to side. Counter weights are added to balance the eccentricity of the Shaft.

Lubrication

Grease nipples are provided at the right places for long life of the bearing.

Crusher Range

| size(Inches) | Motor Rating | Feed Size max. | Average Output In Brass | Speed(rpm) |

|---|---|---|---|---|

| (H.P) | Inches | / 8hours | ||

| 8 x 5 | 5/7.5 | 4 | 1/2 | 300 |

| 12 x 7 | 12.5/15 | 6 | 6/12 | 300 |

| 14x7 | 15/20 | 6 | 8/14 | 300 |

| 16 x 10 | 25/30 | 9 | 14/30 | 315 |

| 20 x 10 | 35/40 | 9 | 24/55 | 325 |

| 24 x 12 | 41/50 | 11 | 50/85 | 315 |

Primary Crushers

| 24 x 18 | 40/50 | 16 | 80/140 | 300 |

| 32 x 16 | 50/60 | 14 | 100/160 | 300 |

| 32 x 20 | 60/75 | 18 | 130/210 | 285 |

| 36 x 24 | 100/125 | 22 | 170/300 | 275 |

| 42 x 32 | 150/175 | 30 | 300/500 | 275 |

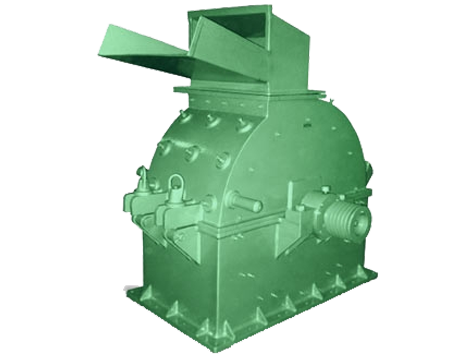

SECONDARY CRUSHER (Granulators)

| 16 x 6 | 25/30 | 5 | 10/30 | 325 |

| 24 x 6 | 30/40 | 5 | 30/50 | 325 |

| 32 x 7 | 40/50 | 6 | 50/70 | 325 |

| 42 x 8 | 50/60 | 7 | 60/100 | 32 |

NEW ADDITION

| 32 x 10 | 50 | 9 | 50/90 | 32 |

| 32 x 12 | 50 | 11 | 60/100 | 31 |

| 48 X 36 | 175/200 | 34 | 400/600 | 275 |

Average Crushing Capacity in tons / hour

| size |

Jaw Settings at Opening shown (in mm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|

| (Inches) | 12 | 19 | 25 | 32 | 40 | 50 | 75 | 100 | 125 |

| 8 x 5 | 1 | 2 | - | - | - | - | - | - | - |

| 12 x 7 | 2 | 3 | 4 | 5 | - | - | - | - | - |

| 14x7 | 3 | 4 | 6 | 7 | - | - | - | - | - |

| 16 x 10 | 6 | 8 | 10 | 12 | 15 | 18 | - | - | - |

| 20 x 10 | 12 | 15 | 18 | 20 | 22 | 26 | 34 | - | - |

| 24 x 12 | - | - | 26 | 28 | 30 | 34 | 40 | - | - |

| 24 x 18 | - | - | - | - | 40 | 48 | 60 | 70 | - |

| 32 x 16 | - | - | - | - | 48 | 56 | 68 | 80 | - |

| 32 x 20 | - | - | - | - | - | 65 | 80 | 95 | 115 |

| 36 x 24 | - | - | - | - | - | - | 95 | 120 | 140 |

| 42 x 32 | - | - | - | - | - | - | - | 160 | 210 |

SECONDARY CRUSHER GRANULATORS

| 32 x 7 | 23 | 28 | 33 | 38 | 45 | - | - | - | - |

| 42 x 8 | 30 | 36 | 42 | 48 | 55 | - | - | - | - |

| 1 Brass = 3 cu.m=100cft=4 Tons (approx) |

|---|

| (Tonnage may depending on the size of feed, rate of feed, operating condition, breaking characteristic & compressive strength of rock. |

|---|

NEW ADDITION

| 32 x 10 | - | 24 | 26 | 29 | 33 | 38 | 45 | - | - |

| 32 x 12 | - | - | 28 | 31 | 36 | 41 | 48 | - | - |

| 48 x 36 | - | - | - | - | - | - | - | - | 260 |

WhatsApp

WhatsApp